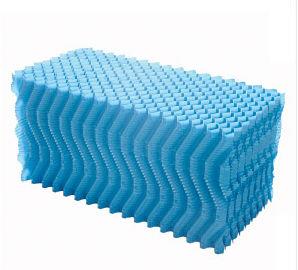

S Corrugated Cooling Tower Filler

S RippleCooling tower FillerProduct Description:

s corrugated cooling tower filler mainly depends on the water in the splash process formed by the small droplets to dissipate heat. In the slabs, large droplets of water from top to bottom continue to fall to the lower slabs are splashed into a lot of small droplets and the surface heat dissipation, get cooled.

In triangular slabs as water filler, hot water mainly depends on the following three parts of the area for heat dissipation: water in the surrounding strip flow formed by the surface of the water heat dissipation, in the lower part of the strip down the surface of the large droplet heat dissipation, large droplets fell to the strip splashed into the surface of small droplets to dissipate heat

The heat dissipation effect of s corrugated cooling tower filler is related to the section shape, strip spacing, vertical spacing of the upper and lower slabs, hydraulic load and air velocity of the strip in the leaching filler.

1, plate shape and arrangement

(1) commonly used slabs have triangles, rectangles, arcs, cross-shapes, M-shaped, Omega-shaped and so on.

(2) commonly used arrangement forms have tilt type, chessboard type, etc., as shown in Figure 3-10.

The wide surface of triangular slabs is mostly arranged upward, although the arrangement is not very convenient, but it is conducive to the splash of water droplets, in the countercurrent cooling tower can reduce ventilation resistance, so the application of a wide range. If the rectangular slabs are arranged horizontally, the splashing effect of the water droplets is better, but in the countercurrent cooling tower, the horizontal rectangular slabs will reduce the area of the airflow channel, thus increasing the ventilation resistance. The rectangular slabs are tilted (the inclination is generally 45°, and the 60° is also used), which can not only reduce the ventilation resistance but also use the inclination to guide the wind.

2. Structural Dimensions

(1) The structural dimensions of the commonly used s corrugated cooling tower filler are shown in table 3-1.

(2) s corrugated Cooling tower filler is basically used in large towers, so the more layers, the higher the height. The number and height of the layer are: the mechanical ventilation cooling tower is the 13~33 layer, and the open drip cooling tower is the 10~23 layer. Countercurrent Mechanical ventilation Cooling tower water filler height is generally 6~8m. (3) 50mm plate width Narrow plate splash condition is good, resistance is small, is s corrugated cooling tower filler commonly used plate wide size. In the transverse flow tower generally use the horizontal placement form, the Countercurrent tower plate can be horizontal or tilt (inclination alpha is generally 60°) arrangement, tilt arrangement can increase the strip positive and negative water film area, is conducive to water cooling. The increase of the vertical distance of the strip can increase the number of small droplets.

3, material strip materials have wood, bamboo slices, wire mesh (or steel bars), concrete slabs, plastic panels and so on.

(1) Wire mesh (or steel bar) cement slab: durable, but the production requirements are high, steel bar straight non-gluten, there is a certain protection thickness. Existing wire mesh or reinforced concrete monolithic slabs or combined block reinforced concrete slabs, as shown in Figure 3-11. Such slabs, such as cracks in the water infiltration, easy to speed up the corrosion of steel bars.

(2) Plastic slabs: mostly made of hard polyvinyl chloride into crosses or T-shaped slabs, mostly used in small and medium-sized cooling towers. Arc slabs made of hard polyvinyl chloride can be used in larger cooling towers, and plastic slabs have excellent corrosion resistance.

(3) Wooden water strip: the surface does not have to be polished to facilitate the formation of water film. The plank strip should be treated with coal phenol miscellaneous oil for antiseptic treatment. Preferably with a non-nail opening structure combination, can also be used galvanized iron nail or bamboo nail mouth combination.

(4) Bamboo Slabs: the choice of growing bamboo or light bamboo, bitter bamboo, to bamboo strength, drying before processing, strip processing with coal phenol miscellaneous oil for anti-corrosion treatment. Assemble bamboo slices first drilling and then nailing, bamboo green face up. It is advisable to use plastic panels, wire mesh or reinforced concrete panels as far as possible, with little or no wood.