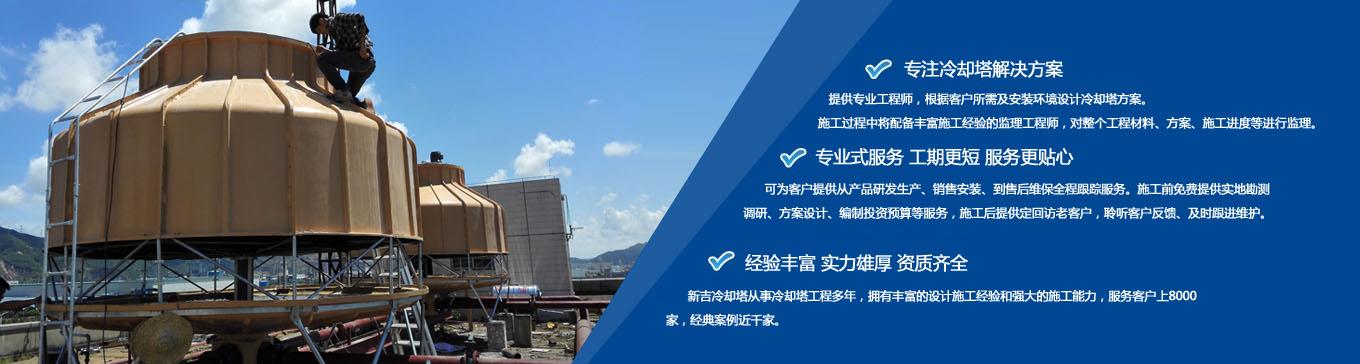

Industrial cooling tower using cast-in-cast reinforced concrete plate

Countercurrent Concrete Cooling Tower Product Introduction:

Industrial Cooling TowerReinforced concrete structure, stainless steel can be used. Reinforced concrete Structure tower, it is advisable to adopt bidirectional frame structure. The reverse-flow concrete cooling tower should adopt bidirectional planar frame structure, and the column should adopt stainless steel pipe.

The structure type, arrangement and size of the countercurrent concrete cooling tower should be determined synthetically according to the requirements of production and structural design.

The Liang of the water filling filler supported by the countercurrent concrete cooling tower is arranged in the direction of inlet, and the spacing of the beams should be increased under the condition of satisfying the requirements of the supporting leaching filler.

The beam supporting the water filler of the countercurrent concrete cooling tower shall be a narrow and high rectangular cross section;

The horizontal projection area of the filler support structure should not be greater than 15% of the area between the tower axes;

Countercurrent Concrete Cooling tower enclosure structure, it is advisable to use FRP wall panels, reinforced concrete wall panels or other lightweight high-strength and corrosion-resistant materials wall panels;

The roof of the reverse-flow concrete cooling tower shall meet the following requirements:

Reinforced concrete structure tower top plate. Cast-in-cast reinforced concrete slab should be used;

Steel structure Tower top plate, should adopt lightweight structure, but should ensure its transverse stiffness;

Reverse-flow concrete Cooling tower mounting accessories:

The Tower Body Wind Guide system includes the air cylinder, the diversion cone, the wind guide umbrella or the diversion ring, the horizontal guide plate and so on accessories. The wind turbine should adopt FRP structure, the gap between the inner wall of the air cylinder and the fan blades should be uniform, and should not be greater than 20mm;

The setting of the diversion cone shall meet the following requirements:

When the fan base is under the column, the guide cone should be set at the top of the column;

When no column is set under the fan base, it should be set under the fan base

The setting of the Air guide umbrella or diversion ring should meet the following requirements:

FRP structure should be used in wind guide umbrella and diversion ring.

The fan diameter is equal to 4. 7m tower should be set to guide the air duct or set gas section of the air cylinder;

The fan diameter is greater than 4. 7m tower should be set to guide the air umbrella or diversion ring;

Horizontal wind guide plate can be selected according to the actual situation of reinforced concrete, steel plate, reinforced concrete and FRP composite structure or reinforced concrete and steel plate combination structure;